Open access for safe productivity

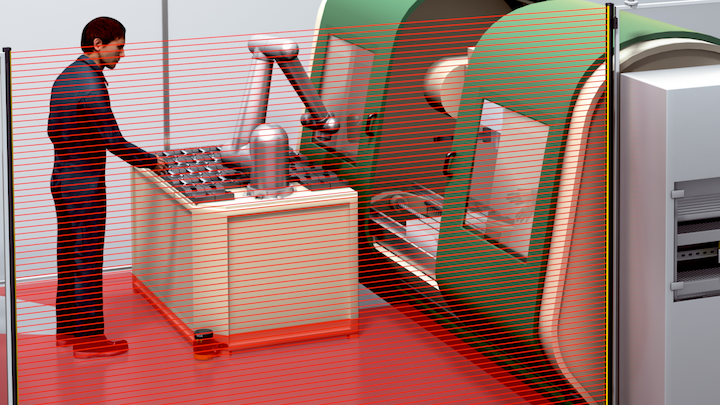

The Safe Robotics Area Protection safety systems from SICK are a starting point for safe human-robot interaction and enable cooperative and freely-accessible robot applications. The system comprises hardware as well as software or functional logic with tested safety functions. Not only generic but also manufacturer-specific variants are available, for example for Universal Robots, FANUC, KUKA and Yaskawa. Thanks to the detailed documentation and robot-specific settings, these variants can be easily integrated into robot control systems and, in part, configured directly via the robot hardware. Safe Robotics Area Protection ensures less downtime, optimized work processes and therefore an increase in productivity.

Safe Robotics Area Protection AT A GLANCE

Benefits

-Free, safe access to cooperative robot applications for less downtime, optimal work processes and high productivity

-Highly flexible and future-proof solution thanks to easy tailoring of the systems to the specific robot application and production environment

-Time-saving configuration of the systems, in part directly via the robot hardware

-Detailed documentation, compliant with relevant standards

-Low costs as the system is easy to integrate into industrial robot controllers, thanks to generic or manufacturer-specific variants for Universal Robots, FANUC, KUKA and Yaskawa

Features

-Comprising hardware as well as software or functional logic with tested safety functions

-Generic and manufacturer-specific variants (Universal Robots, FANUC, KUKA, Yaskawa)

-Documentation with wiring diagram, SISTEMA file and operating instructions

-Automated robot restart possible

-Performance level (PL) d

ADVANTAGES

Safe productivity with Safe Robotics Area Protection

Safe productivity with Safe Robotics Area Protection

With Safe Robotics Area Protection, SICK is offering safety systems which serve as the basis for quick and easy protection of freely-accessible robot applications. This means that, in addition to complete safety, it enables the highest levels of productivity. The focus is on close and safe collaboration between humans and robots. Safe Robotics Area Protection has the right system for every application: The sBot Speed and sBot Speed CIP systems reduce the robot speed when approached appropriately, while the sBot Stop system triggers a safe stop.

Increase productivity

Thanks to freely-accessible robot applications with reduced speed, prevention of unnecessary machine stops and the option of automated restart.

Stay flexible

Thanks to individualized adjustment of safety systems and modular expansion, making it possible to arm yourself for changing requirements and future challenges.

Save time and money

Thanks to pre-selected safety hardware components, safe, pre-configured and tested control logic, and detailed documentation. This makes integration into your robot control quick and easy.

Increase your productivity for robot applications

With speed reduction for fewer downtimes

With speed reduction for fewer downtimes

The sBot Speed system variants adapt robot operation to the respective position of the worker, thus reducing downtime, optimizing workflows and increasing productivity. On the hardware side, they consist of a safety laser scanner, the Flexi Soft safety controller or the robot controller, thus enabling both safety and flexibility. sBot Speed can be easily integrated into the most common robot controllers thanks to robot-specific settings and detailed documentation, and configured directly via the robot hardware (UR Teach Pendant) thanks to sBot Speed – URCap.

High machine availability

Thanks to speed reduction and the option of automated restart, you can reduce downtime.

Flexible safety system

Optimally adapt the fields of the safety laser scanner to the application environment and implement additional safety functions into the safety controller at any time.

Increase your machine availability with sBot Speed

sBot Speed is available in different variants:

sBot Speed (manufacturer-specific)

sBot Speed – YA (YASKAWA)

sBot Speed – UR (Universal Robots)

Reduction in robot speed thanks to field set switchover with the option of automated restart.

sBot Speed – URe (Universal Robots)

Simultaneous protective field monitoring with automated or manual restart.

sBot Speed – URCap (Universal Robots)

Simultaneous protective field monitoring with automated restart as well as simple and time-saving configuration of the nanoScan3 safety laser scanner via the Teach Pendant of the eSeries robot from Universal Robots.

More options for challenging robot applications

More options for challenging robot applicationsThe sBot Speed CIP system variants are available for both FANUC robots (sBot Speed CIP – FA) and KUKA robots (sBot Speed CIP – KU) and enable safe simultaneous monitoring of multiple protective fields. This makes this safety system suitable for freely-accessible robot applications in which persons can walk behind the protected area, for example in palletizer systems. The system variants combine the microScan3 Core – EFI-pro safety laser scanner with the Flexi Soft safety controller and the EFI-pro gateway. Thanks to EtherNet/IP™ CIP Safety™ and the robot-specific settings of sBot Speed CIP, the system variants can be integrated into the robot controller quickly and safely. In addition, communication between safety system and robot control is easy to set thanks to the pre-configured parameters.

EtherNet/IP™ CIP Safety™

Benefit from optimal, safe robot integration, the ability to set additional functions, and reduced cabling requirements.

All-around protection

Simultaneous field monitoring enables the protection of applications that can be freely accessed from behind.

Easy integration and protection of applications accessible from behind thanks to CIP Safety

The simple solution for immediate automated restart

The simple solution for immediate automated restartThe generic variant sBot Stop allows a compact machine design with a minimal safety distance to the hazardous area thanks to a combination of safety laser scanner, safety light curtain or multiple light beam safety device, and a Flexi Classic safety controller. Safety functions are available as prefabricated, tested functional logic for the non-programmable Flexi Classic safety controller and can be selected quickly and easily using a rotary switch.

The sBot Stop – URCap system variant, which combines the advantages of a safety laser scanner for protection with the intuitive sBot – URCap software, allows the safety system to be configured and operated quickly and easily directly via the robot hardware (Universal Robots Teach Pendant).

Save time

Thanks to the possibility of quick and easy configuration via rotary switch or intuitive software.

Simple and intuitive

Thanks to the possibility of quick and easy configuration via rotary switch or intuitive software.

Benefit from easy handling

sBot Stop is available in different variants:

sBot Stop

With 11 different variants to choose from, we have the right solution to quickly bring your machine to a safe stop.

sBot Stop – URCap

Configure the safety system quickly and easily directly via the Teach Pendant of the eSeries robot from Universal Robots.

Untitled

Untitled

Inquiry - Safe Robotics Area Protection