High performance 2D LiDAR sensor for navigation of automated guided vehicles

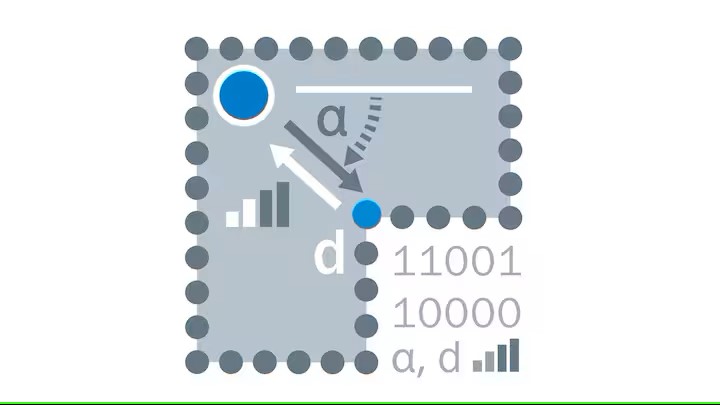

The 2D LiDAR sensors in the NAV product family provide the highest level of performance for the navigation of automated guided vehicles (AGVs). The unrestricted spatial location of positions is performed using reflector marks and provides the AGV with maximum flexibility by virtually changing the route in the vehicle computer. NAV 2D LiDAR sensors provide highly accurate spatial contour data about distance, angle, and remission, as well as reflector data, at high speed over a scanning path of up to 360 degrees. Multiple measurements made on each reflector are converted into precise reflector coordinates. This information makes it possible to transmit the precise vehicle position to the vehicle computer, even if ambient conditions change. The combination of spatial contour data and reflector data (mixed-mode navigation) enables line-guided vehicles to travel in areas where it is not possible to position reflector marks (automated truck loading or block storage areas, for example).

NAV3xx AT A GLANCE

Benefits

-Precise, fast collection of spatial contour data and/or simultaneous determination of reflector data (managing up to 12,000 reflectors) in real time

-Integrated evaluation of measured data reduces the computing load in the vehicle computer, minimizing power consumption and reducing operating costs

-High flexibility, since line guidance is also possible in areas without reflector marks, and routes can be easily modified using teach-in mode

-Precise measurements in harsh industrial environments thanks to IP65 housing for indoor applications

-High angular resolution for gap-free scanning even under difficult conditions

-Hardware synchronization output ensures precise control

Features

-Mixed-mode navigation provides both spatial contour data and reflector data

-Long scanning range: up to 70 m on reflectors (up to 35 m on black targets)

-High internal computing power and individual AGV configuration

-Measurement, navigation, and determination of position with highest level of precision from three visible reflectors

-Angular resolution of up to 0.1 degrees

-Navigation, spatial and contour data, reflector marks, angular position and/or raw data collection

ADVANTAGES

NAV series – Precise measurement of natural landmarks (contour data) right through to localization based on detected reflector positions – flexibility of today.

NAV series – Precise measurement of natural landmarks (contour data) right through to localization based on detected reflector positions – flexibility of today.

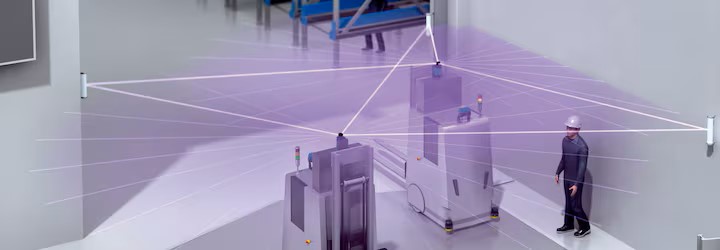

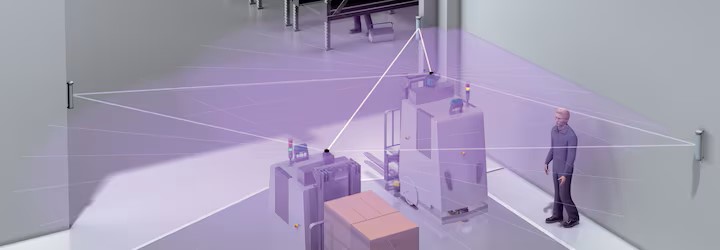

Today's LiDAR-based localization systems for automated guided vehicle (AGV) systems or autonomous mobile robots (AMR) determine their current position based on ambient data. They do this using contour data (natural landmarks) or also the position data of installed reflectors. Vehicle speed, surface characteristics of the vehicle’s route, or frequently changing (dynamic) ambient conditions necessitate so-called mixed mode operation in some areas.

The sensors in the NAV series offer a special feature: The acquisition of contour data and optional simultaneous detection of reflector positions are supported in the same variant. This combines the advantages of both technologies for localizing autonomous vehicles in industrial environments.

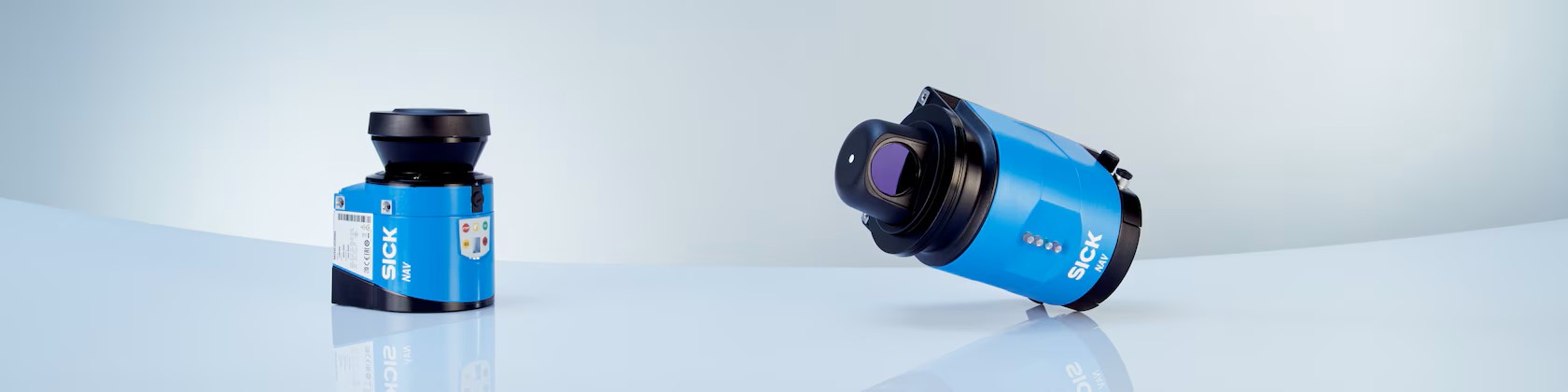

NAV2xx

The compact and rugged NAV210 and NAV245 sensors are the first choice for medium and smaller automated guided vehicle (AGV) systems. The precise acquisition of ambient data and concurrent output of reflector positions provide the basis for precise and highly dynamic navigation in warehouses (and refrigerated areas as well). If required, the contour or reflector positions or also both data packages can be output together.

NAV3xx

The sensors in the NAV3xx product family are the right choice for localizing larger automated guided vehicle (AGV) systems. Thanks to the large scanning range of up to 250 m, the sensors can detect contours or reflectors even in wide and open areas or long corridors.

Rugged and reliable measurement data acquisition meets flexibility: The output logs of the NAV product family make it possible to utilize the raw data, reflector positions or also the current vehicle position.

Reliability and flexibility – the right characteristics for effectiveness and success have been combined in the NAV product family

Reliability and flexibility – the right characteristics for effectiveness and success have been combined in the NAV product family

The 2D LiDAR sensors in the NAV product family from SICK meet the current requirements on modern automated guided vehicles (AGVs): A reliable measurement technology that is fit for everyday use is the basis for success and profitability in many industrial applications.

NAV2xx

Small and medium sized vehicles require sensors with a compact design that promise reliable and fault free operation. The sensors in the NAV2xx product family ensure both, and are therefore used for example to determine the position of tuggers in warehouses or also for cleaning robots.

Selection guide according to product characteristics:

- Output log for contour data and/or reflector data; mixed mode navigation possible

- SOPAS tool: Parameterization, visualization

- Ambient operating temperature: –30 °C-+50 °C

- Scanning frequency: 25 Hz

- Working range up to 50 m; to reflectors: 30 m; to targets with 10% remission: 18 m

NAV3xx

To localize larger and more complex vehicles, it is essential to have a large scanning range as well as a measuring angle over 360°. This provides ambient data with an all-round view within a radius of up to 500 m. Data in large assembly halls/terminals or in long corridors.are reliably acquired. Contours and/or reflector positions are detected even over large distances.

Selection guide according to product characteristics:

- Output log for contour data, reflector positions and vehicle position

- SOPAS tool: Parameterization, visualization, layout determination, layout checking, position calculation

- Ambient operating temperature: 0 °C–+50 °C

- Scanning frequency: 8 Hz

- Large working range up to 250 m; to reflectors: 70 m; to targets with 10% remission: 35 m

The devices in the NAV3xx product family are characterized by their high flexibility and suitability for a wide variety of applications. Whether it be raw data, the position of the reflectors, or even the precise actual position of the vehicles that needs to be determined: The devices in the NAV3xx series are up to the challenge and collect reliable data throughout an entire area up to a maximum distance of 250 meters.

The devices in the NAV3xx product family are characterized by their high flexibility and suitability for a wide variety of applications. Whether it be raw data, the position of the reflectors, or even the precise actual position of the vehicles that needs to be determined: The devices in the NAV3xx series are up to the challenge and collect reliable data throughout an entire area up to a maximum distance of 250 meters.

Output log for contour data, reflector positions and vehicle position,SOPAS tool: Parameterization, visualization, layout determination, layout checking, position calculation, diagnostics

Large working range up to 250 m; to reflectors: 70 m; to targets with 10% remission: 35 m

Integrated calculation and output of the vehicle position (x, y, and angle),Output of raw contour data as distance, angle, and remission values ,For the data log: (raw data, reflector data, position output) up to 12,000 position values for different reflectors can be stored in the device, i.e., flat and round reflections can be used at the same time.

Flexible data output because customizable

NAV3xx - The right solution when you need a large scanning range and, at the same time, reliable detection of ambient data.

Inquiry - NAV3xx